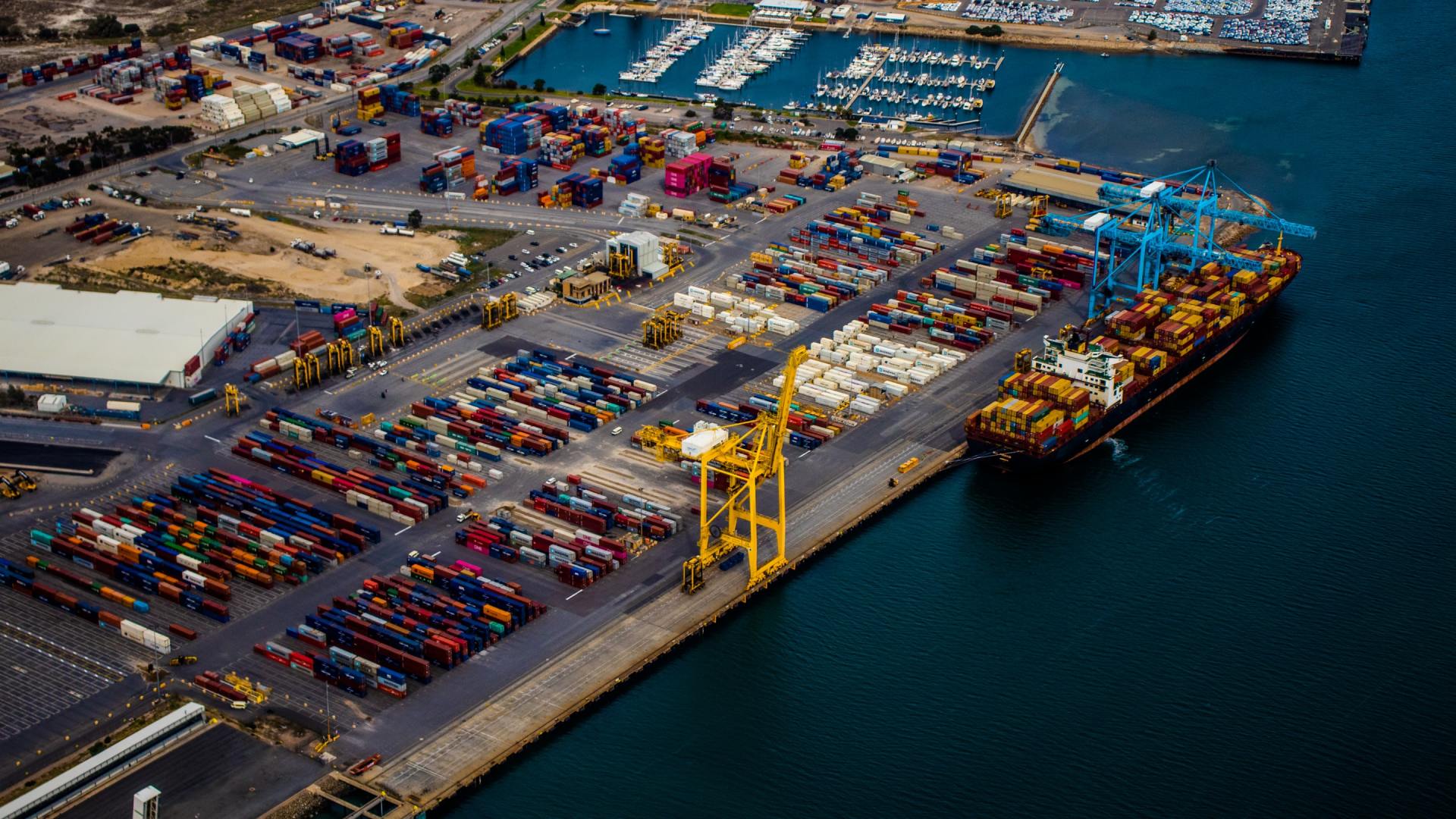

South Africa is a world leader in mining. The country is famous for its abundance of mineral resources, accounting for a significant proportion of world production and reserves. In addition to gold and diamond reserves, South Africa is also the 7th largest coal-producing country in the world. With South Africa’s economy built on gold and diamond mining, the sector is an important foreign exchange earner, with gold accounting for more than one-third of exports.

According to the analysis of the Global Mining Survey Report by KPMG in 2020, mine accidents and environmental safety are some of the main challenges faced within the mining industry. Accidents affect the safety and wellbeing of on-site employees, negatively affecting companies implementing Corporate Social Responsibility policies.

Fully connected with reliable, high-performance wireless communications

Application

Secure and stable communication is established for connectivity between 100 mining vehicles and various mobile production items including prospecting, mineral separation, mining, conveyor, and security monitoring equipment.

Executive Summary

There are many health and safety challenges within the mining industry. In an ever-increasing competitive environment, mining companies are constantly investing in cutting-edge technology and equipment to improve productivity. The dangerous nature of mining often creates a skills gap between experienced miners and new recruits, which is where technology and communication equipment becomes paramount in keeping systems and information flowing smoothly.

Heavy machinery, especially large vehicles are used extensively within a mining environment. Operators of these vehicles require robust communication platforms to safely move goods in and around a site. By adopting a digital management solution, mine managers can monitor data and operating systems in real-time to increase efficiencies, reduce costs and save lives. To maintain the consistency and reliability of operations, a secure and stable communication solution is required between the management control center and mining vehicles.

Challenge

Due to its volatile environment, a coal mine can be an extremely challenging place to communicate. There are threats from flammable gases, severe electric wave interference, narrow spaces, and large distances to cover. The challenge of effective, real-time connectivity between a central control office and various mission-critical equipment requires the following features:

- Constant, area-wide connectivity

From large open areas to underground operations, connectivity equipment must be permanently active to ensure seamless remote monitoring and communication. A connectivity layer interruption or service outage could severely affect the productivity of the mine resulting in financial losses, damage to equipment, and even loss of life.

- Vibration and temperature resistance

Heavy-duty vehicles generate vibration and turbulence as they collect and deposit large amounts of resources within the mine. Operating temperatures in excess of 40`C are common in South African conditions. Relying on a standard LTE router within such a hazardous environment will result in the router being severely damaged.

- Reduction of hidden cost

Traditional ‘fixed line’ communication is not cost-effective within a mining environment due to the harsh nature of the mine and regular infrastructure maintenance. Standard routers are not designed for such harsh environments, frequently needing to be replaced, repaired, or re-set to establish connectivity.

- Maximum mining efficiency

Another crucial element for effective communication is the ability to ‘pin-point’ the mine's vehicles. Using a GPS positioning system allows the mines Control Office to accurately map and dispatch vehicles with maximum efficiency. Large volumes of data collected from the vehicles can be processed in real-time to manage performance, consumption and improve productivity.

How Billion Helped

Billion M120N Enables Wireless Mobile Connectivity on 100 Mine Vehicles

Connecting Equipment with extremely High Integration

All-in-one (industrial specifications, in-vehicle, GPS, hotspot, dual WAN, backup)

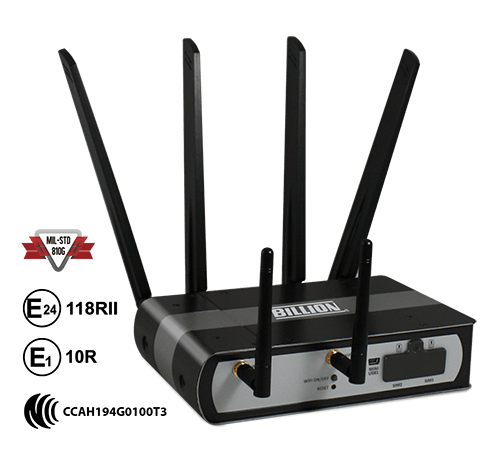

LTE Industrial/In-Vehicle Multi-Carrier Router

Billion Electric provides an industrial all-in-one in-vehicle Billion M120N router with high performance and wireless communication enabling high availability, reliability, and secure connectivity. The compact, rugged design integrates dual SIMs, four Gigabit Ethernet ports, Wi-Fi access points, embedded multi-GNSS receiver for GPS or GLONASS, and ignition sensing for in-vehicle applications. The M120N is a communication product designed for automation applications and digital information integration in the mining group.

Industrial wide‑temperature specifications

- Designed for challenging and rugged environments.

- Hardened enclosure with industrial-grade components.

- Enabled to work stably in environments at temperatures of -40°C – 60°C.

Simple deployment for easy management

- Compact design with installation instruction for easy installing.

- Applicable installation for various kinds of vehicles with ignition sensing to automatically sense the engine ignition status of the vehicle. It will shut down automatically according to the set delay time when the vehicle stalls to prevent running out of battery power.

- Embedded GNSS component for real-time positioning.

Serial port (DB-9 female)

- RS-232/RS-485 to connect with other peripherals such as a sensor.

- Support Modbus/TCP, Telnet server, SSH server, UDP server/client and TCP server/client.

Wireless sharing

- Compliant with IEEE 802.11n standards.

- Wi-Fi hotspot with Captive Portal.

High performance and reliability

- Multi-WAN: Dual SIMs and GbE WAN to realize flexible and reliable connection.

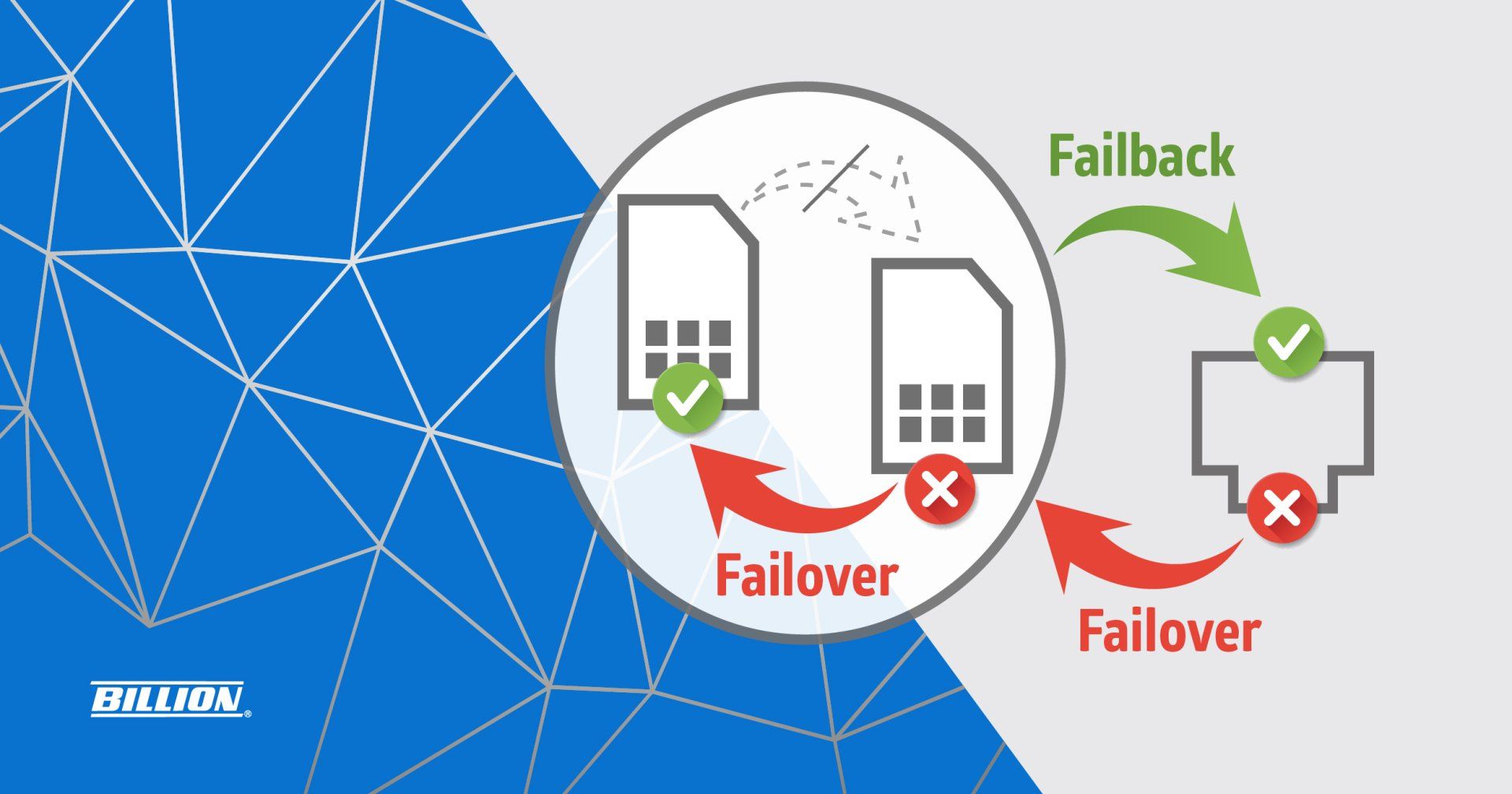

- Bandwidth extensibility – Load balancing and reliable connection – Auto-failover/failback.

How Failover/Failback Function Works?

Failover/Failback Function from Billion

When network equipment is disconnected from the Internet, resulting in the disconnection of applications, the connection must be restored as soon as possible in order to minimize the risks of network loss and relevant losses.

▶

How Failover/Failback Function Works?

▶

9 ways to Improve your Wi-Fi router speed

▶

Ensuring Business Continuity with Advanced Failover/Fallback and VPN

Conclusion

The ULTIMATE Digital Management Solution for Mine Safety - Billion Electric and 3rd Party System Integrators Develop ‘Early Warning’ Functionality for South African Mines

Provide reliable and stable connectivity, to ensure the normal operation of connected equipment and applications

To successfully enable digital integration solutions for the mine's wireless network infrastructure. Billion Electric works with system integrators to provide wireless mobile network connectivity between mining vehicles and the mine's central control office. Secure and stable communication is established for connectivity between 100 mining vehicles and various mobile production items including prospecting, mineral separation, mining, conveyor, and security monitoring equipment.

More agile, simple, and flexible connectivity applicable to ever-changing customer demands (including various remote working demands)

The Billion M120N can be integrated with various in-vehicle systems. The high extension capability of 4 x GbE WANs and 1 RS-232/RS-485 allows for the successful integration of numerous types of monitoring equipment, for optimal digital management. It can switch automatically to provide a mobile network hotspot in the quarry for employees to receive the latest status online and stay in touch with the central control office, without interruption. It supports GPS positioning and a smart dispatch system to conduct control and management throughout the loading, carrying, and unloading processes of the mining vehicles.

Real-time image monitoring and transmission

Due to the bulky size of the mining vehicles, safety accidents can easily occur due to the ‘blind spot’ of the driver. The image system and infrared detecting system is installed on each visual angle of the mining vehicle to prompt the driver via image or warning if there are pedestrians or other equipment around the vehicle. The data and messages related to the monitored video are promptly sent to the central management platform and displayed on the screen of the vehicle. The operator receives the message to activate the smart security monitoring system.

Achieve reliable and consistent connectivity

The Billion M120N integrated with multi-WAN can automatically fail-over to a backup connection. The dual SIMs can deliver mutual backup via LTE communication to provide a highly reliable uninterrupted connection. By installing a durable Billion M120N, a constant connection is maintained with the mining vehicle, allowing for timely image transmission. The monitoring system sends various data detection reports regularly to the control office to achieve digital automation and message integration. In the case of an emergency, it can request real-time assistance, respond quickly or conduct automatic protection to ensure a safe working environment for the field operators and Mine personnel.

Reliable, stable, and secure VPN network

Billion M120N supports various VPN protocols, including IPSec, PPTP, L2TP, GRE, and OpenVPN. By using a Virtual Private Network (VPN), built-in Network Address Translation (NAT) firewall, password protection for system management, and the system’s capability to prevent DoS attacks, including Land Attack and Ping of Death, the malicious attack is blocked to secure data transmission security and provide protection for the financial data confidentiality of enterprises.

High stability with low repair cost

The temperature resistance, anti-vibration design of the Billion M120N can withstand the harsh mining environment experienced by the vehicle during operation. The robust design of the router ensures minimal maintenance and vehicle downtime. Its ignition sensing can automatically detect ignition and shutdown to prevent running out of battery power.

Dual network backup VPN to create the ideal digital management solution

The digital management solution for Mine safety.

Billion Electric and system integrators successfully developed a wireless mining solution to assist mining groups in improving the reliability and stability of communication equipment via cameras. The system improved the safety and productivity of the mine by enhancing operating efficiency and helped reduce production costs.